Unlock Limitless Possibilities with Precision CNC Machining

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | F304L F316LN Exc | Process | Machining |

|---|---|---|---|

| Standard | Custom | Surface | Polished |

| Application | PVD Vacuum Coating Food& Bevera | Shape | Cylindrical, Box, D-shape, Spherical, Polygon, Bell Jar, Custom |

| Highlight | Limitless Possibilities CNC Machining,Unlock Limitless Possibilities CNC Machining |

||

Unlock Limitless Possibilities with Precision CNC Machining

In the modern age of manufacturing, few technologies have been as transformative as computer numerical control (CNC) machining. What began as a revolutionary concept in the late 1940s has evolved into an indispensable process, forming the foundation of countless industries. From medical technology and aerospace to electronics, automotive, and industrial machinery, CNC machined components are ubiquitous, enabling design freedom, production efficiency, and unsurpassed levels of precision.

At DM, we stand as pioneers in realizing the boundless potential of CNC machining. With over 15 years of experience pioneering this remarkable technology, our expertise, advanced capabilities, and uncompromising pursuit of excellence allow us to deliver unparalleled manufacturing solutions that drive innovation across sectors.

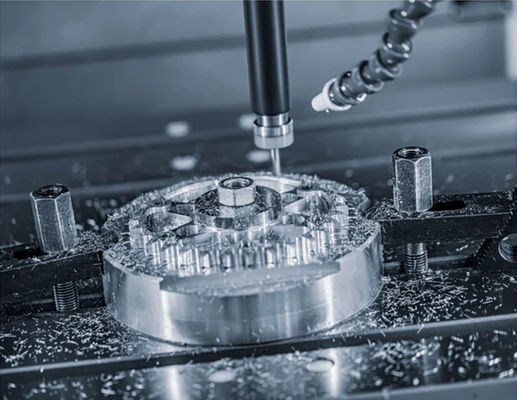

The Art and Science of Subtractive Manufacturing

At its core, CNC machining is a subtractive process that harnesses the power of computer controls to methodically guide cutting tools in removing material from a solid block or billet. This intricate dance of precision enables the creation of virtually any geometry, no matter how complex, within astoundingly tight tolerances of up to ±0.025mm (0.001 inches).

Our state-of-the-art CNC machining facility offers a comprehensive arsenal of manufacturing technologies to cater to projects of any scale and complexity:

CNC Turning: Ideal for manufacturing cylindrical and rotational components by spinning the raw material while advanced cutting tools shape the exterior geometry with mirrored precision.

CNC Milling (3/4/5-Axis): Our cutting-edge multi-axis CNC mills unlock unlimited geometrical versatility, effortlessly producing even the most intricate contoured shapes and cavities in a wide range of materials.

CNC Drilling: From creating precise hole patterns and slots to deep-hole drilling applications, our high-speed CNC drill machines deliver unmatched efficiency and repeatability.

CNC Routing: Leveraging computer-controlled cutting heads, our CNC routers offer phenomenal accuracy in cutting sheets of plastic, wood, aluminum, and more.

CNC Waterjet Cutting: This innovative cold-cutting process combines highly pressurized water with an abrasive substance to cut through virtually any material with ease, producing no heat-affected zones.

CNC Laser & Plasma Cutting: Harnessing the power of focused energy beams, these non-contact cutting methods provide superior quality and edge integrity when cutting sheet metal, plate, and tubing.

The DM Difference: Mastery of the Full Manufacturing Workflow

While our technological capabilities are immense, what truly sets [Company] apart is our comprehensive mastery of the entire CNC production workflow. We take an exhaustive approach from the conceptualization and design engineering phase through CAD/CAM programming, machine setup, cutting parameters, post-machining processes, and more.

Our experts, backed by decades of cumulative experience, leverage this 360-degree perspective to optimize every aspect of the manufacturing process. Critical variables like tooling, speeds, feeds, chip loading, and surface speeds are carefully calculated and fine-tuned based on the specific material, geometry, and tolerance requirements. This uncompromising attention to detail ensures supreme tool life, impeccable surface finishes, and absolute part integrity.

To deliver truly remarkable solutions, we go beyond technical prowess alone. Our teams establish deep collaborative partnerships with each customer, engaging in thorough discussions and design reviews to gain a comprehensive understanding of the application requirements, performance specifications, and nuanced preferences. With these insights, we judiciously select the ideal material and manufacturing approach to guarantee success.

Material Mastery and Flexibility

DM's cutting-edge CNC machining capabilities extend across a vast array of metallic and non-metallic materials including:

• Ferrous Alloys: Stainless Steels, Tool Steels, Alloy Steels

• Non-ferrous metals: Aluminum, Brass, Copper, Titanium

• Plastics: PEEK, PPSU, PTFE, Nylon, Polycarbonate

• Exotic Materials: Hastelloy, Inconel, Molybdenum, Tungsten

This incredible material flexibility, combined with our ability to run lights-out automated overnight production, empowers us to manufacture any component with remarkable speed and cost-efficiency. From prototypes to production runs, we scale our operations to cater to programs of any volume.

Relentless Commitment to Quality and Service

At DM, quality is more than just a buzzword – it's a foundational pillar. Our facilities are ISO 9001 certified and employ stringent quality management systems with multiple inspection points and rigorous quality control processes. We uphold the highest standards and leverage cutting-edge metrology, measurement, and inspection solutions to validate